The Product Development Process: A Guide for Inventors

Developing a new product and bringing it to market is a thrilling but demanding process for inventors and startups. I’ve worked on dozens of projects so far and I want to share my knowledge on the process to help inventors and product developers along their journey. This guide is targeted towards physical prototypes but the stages of proof of concept, MVP, and functional prototype can also be adapted to software development.

– Nicholas Sion, October 2023

Key Takeaways

- Additive Engineering is great for assisting with your product development.

- Product development is a structured process that transforms an idea into a manufacturable and marketable product consumers want.

- Following a phased development process reduces risk, accelerates time-to-market, and increases the likelihood of product success.

- Collaboration across design, engineering, marketing, operations, and other teams is crucial for efficient product development.

- Prototyping and testing repeatedly with customers is essential. It makes sure your product is exactly what people are looking for.

- Manufacturing planning in parallel with development enables a smooth transition into production and launch.

- Monitoring post-launch performance and customer feedback enables continual product refinement and improvement.

What is Product Development?

Product development is the process of creating a new product and bringing it to market. The stages of product development will help you transform an idea into an end-use product. I wanted to make it follow a structured approach similar to what I’ve done for a lot of clients in order to reduce risk and optimize the likelihood of launching a successful product through multi-disciplinary efforts including creativity, design, engineering, sales, and marketing.

Why is the Product Development Process Important?

Following a product development process is important for several reasons, including but not limited to:

- Reduces risk – A structured development approach helps identify potential problems early when they can be more easily addressed and solved.

- Optimizes funding – If an idea fails, staged development will not have excessively wasted money on later development.

- Increases product quality – Testing and validation at each stage ensures the product will delight customers when launched.

The Product Development Phases

While product development models can vary across companies or inventors, product design and development generally follows these main stages:

1. Ideation

This initial stage involves idea generation for new products. In my experience, ideation happens most often when someone has a passion for a certain topic or hobby. Example being I had this one client who was passionate about fishing and as such came up with a product for it.

Ideation can also happen through brainstorming, consumer research, identifying market gaps, building on existing IP, or leveraging new technologies.

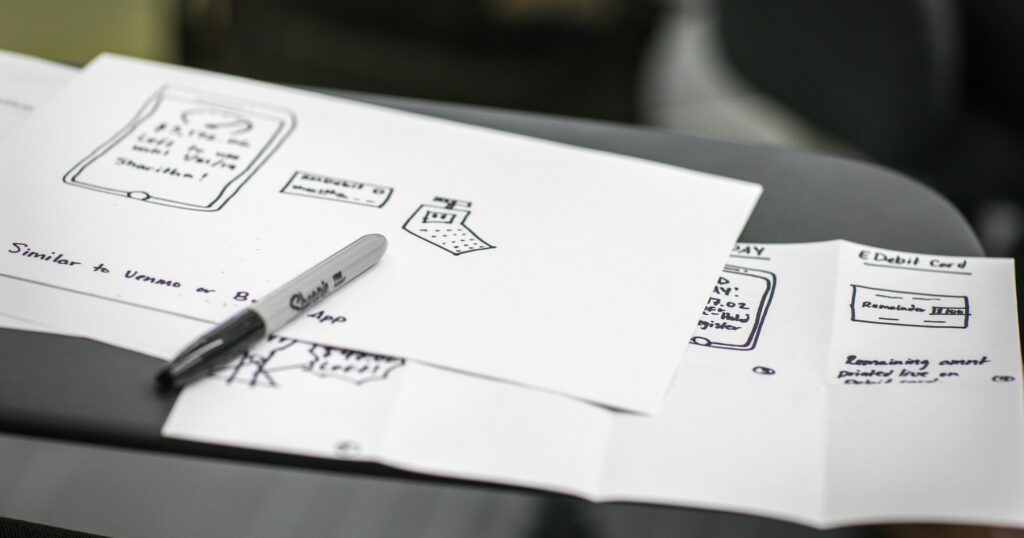

Sketches are incredibly useful when designing CAD models and for understanding functionality.

Activities in this phase:

- Coming up with the idea in the first place

- Initial product concept/sketches if relevant

- Market research

- Consumer needs research

- Competitive benchmarking

- Current technology assessment

Questions to answer:

- What consumer pain point does it address?

- How big is the potential market opportunity?

- What competitive advantages can we leverage?

2. Proof of Concept

This stage involves developing the initial idea into a proof of concept. It can be super rudimentary as long as it proves your idea works. For example, if I were developing a smoke detector, I wouldn’t need the outer casing at this point. All I would want is the electronics to actually detect the smoke.

Activities in this phase:

- Detail customer/product requirements

- Outline potential features and functionality

- Come up with a high-level features list

- Specify minimum viable product (MVP) scope

Questions to answer:

- Who is the target market or target audience?

- What features are must-haves vs. nice-to-haves? You will be focusing on the must-haves for a proof of concept.

- How will this concept stand out from alternatives?

3. Minimum Viable Product

Here the initial proof of concept is taken one step further. A Minimum Viable Product (MVP) will have more features, just enough for the first clients to use, maybe even just friends and family at this stage. These beginning clients will be able to give you feedback before finalizing with a functional prototype.

Activities in this phase:

- Technical assessment of capabilities

- Concept testing with customers

- Intellectual property due diligence

- Supplier capability assessment

- Financial modeling

- Prototype cost estimation, other financial projections if relevant

MVPs aren’t and don’t have to be pretty.

Questions to answer:

- Can our engineers design and develop this product?

- Do we have the manufacturing capabilities or supply chain for this?

- Does this align with our business growth strategy?

- Does the financial modeling support the investment?

- Is there demand signal from initial concept testing?

4. Functional Prototype

Your product will now come into the final prototyping stage using feedback from the initial clients. You’ll have a detailed product definition with all features outlined, determining all the physical elements necessary. These last three stages are where Additive Engineering excels.

If you’re an inventor choosing to license, the functional prototype is probably the farthest you’ll need to go to secure a deal with a licensee.

Activities in this phase:

- Detailed product specifications

- Final mechanical and manufacturing design

- User experience design

- Functional Prototype CAD models

- Prototype units

- User experience maps

Questions to answer:

- What are the technical specifications and bill of materials?

- What industrial design language aligns to our brand?

- What user journeys will deliver the optimal experience?

- How will we architect the electronics and software if present?

5. Product Testing

Hopefully you had the chance to test your minimum viable product, but now is the time to further test with clients with low-volume manufacturing before mass manufacturing. It’s super important to get as much client information as you can before you commit to a manufacturer.

Activities in this phase:

- Functional testing against use cases

- Testing with friendly customers

- Environmental stress testing

- Addressing defects uncovered from user feedback

Questions to answer:

- Do the industrial designs meet the specs and look/feel right?

- How close do the prototypes replicate the actual product?

- What issues need addressing prior to launch?

6. Manufacturing

While testing wraps up, manufacturing planning gets underway to prepare for production. This involves detailed production engineering and supply chain coordination. Additive Engineering can recommend manufacturing methods based on your product and requirements.

Sometimes you can license, sometimes you can manufacture yourself, but sometimes you need to outsource to a larger manufacturer.

Activities in this phase:

- Taking in client feedback

- Finalizing bill of materials

- Designing packaging

- Selecting manufacturing method and equipment

- Developing technical specs for suppliers – production ready diagrams

Questions to answer:

- What production processes will we use?

- Which parts will be made in-house vs. outsourced?

- How will the product be packaged and shipped?

- Are suppliers qualified for mass production?

- What quality checks need implementing?

7. Product Launch

After all the preparation, it’s time for a commercial release. This requires aligning sales, marketing, and distribution efforts to successfully introduce the product and manage growth. Launching the product once the manufacturing is complete can be the most overwhelming part of the process, but making it this far already means people believe in your invention.

Activities in this phase:

- Inventory build-up

- Sales training

- Lead generation

- Marketing/website launch campaign

- Order fulfillment process

- Managing demand vs. supply

The hardest but most satisfying part of the process.

Questions to answer:

- Are sales teams trained on the product benefits and competitive positioning?

- What launch activities will generate buzz and awareness?

- What will the marketing strategy be?

- Can our supply chain handle the initial demand surge?

8. Post-Launch Review

Launching is not the end. It’s critical to monitor the product’s performance and customer feedback post-launch to still be making refinements and improving future iterations. You may get the idea of a future product from client reviews.

Activities in this phase:

- Tracking sales metrics

- Getting customer feedback

- Addressing defects or returns

- Analyzing marketing program performance

- Planning product upgrades

Remember to keep looking for idea improvements or new ideas entirely!

Questions to answer:

- How are sales tracking to projections?

- What product improvements or new features do customers want?

- What defects or returns need addressing?

- How can marketing be optimized?

- What’s the roadmap for future upgrades?

For inventors and startups, navigating the product development maze is much easier when partnering with an experienced development firm. We, Additive Engineering, simplify the process of launching new products. We accelerate product development by offering unmatched end-to-end rapid prototyping services, design, engineering, testing, and manufacturing services.

Our end goal is to help inventors make stuff because when we were making stuff just by 3D printing, there’s a kind of passion that goes into creating something new. That’s also why I made this guide, I hope it not only boosts our SEO but can also help guide a product journey.

Key Takeaways

- Product development is a structured process that transforms an idea into a manufacturable and marketable product consumers want.

- Following a phased development process reduces risk, accelerates time-to-market, and increases the likelihood of product success.

- Cross-functional collaboration across design, engineering, marketing, operations, and other teams is crucial for seamless product development.

- Prototyping and testing repeatedly with customers is essential to create a product that meets user needs.

- Manufacturing planning in parallel with development enables a smooth transition into production and launch.

- Monitoring post-launch performance and customer feedback enables continual product refinement and improvement.